Overload Safety Devices (Torque Limiter Couplings)

Zero-Max’s Torq-Tender® overload safety devices incorporate torque limiters for dependable overload protection. When a jam-up or excessive loading occurs, the built-in torque limiter provides quick and reliable release capabilities, preventing system damage.

Contact us for more information regarding Zero-Max’s mechanical torque limiter overload safety devices. Or, click here to find your local sales representative.

Mechanical Torque Limiter Advantages

The Torq-Tender overload safety device is tamper-proof. Once installed, the torque "trip" torque value cannot be changed. This feature ensures the integrity of the machined design and renders costly and potentially risky calibration procedures unnecessary. Torque value is controlled by the part number ordered; that value determines what spring set is used during the assembly of the torque limiter.- Torque values can be changed in the field. However, the torque limiter must be disassembled and replaced with different springs to achieve the new torque value.

- Standard Torq-Tenders are bi-directional. Torque value remains the same regardless of rotation. If specified, the torque limiter can be configured at the factory to release at different torque values for different rotational directions.

- When used as a coupling, the Torq-Tender fulfills two functions: 1) A flexible shaft coupling; and 2) a mechanical torque limiter.

- In the shaft-to-shaft configuration, the Torq-Tender can accommodate angular shaft misalignment up to 1.5° and parallel misalignments from 0.005” to 0.015”.

- The enclosed design of the mechanical torque limiter enables it to operate in a wide variety of industrial environments. Custom designs and materials can meet unique requirements and withstand even the most adverse conditions.

- Every Zero-Max Torq-Tender overload safety device is made from durable heat-treated steel for long operational life.

How Torque Value is Determined

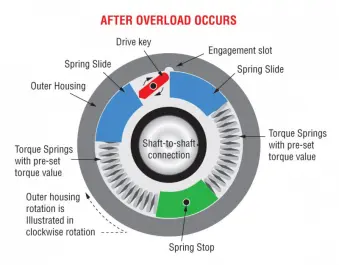

The “trip” torque value of a Zero-Max Torq-Tender is determined by the force of the installed springs in the unit. The spring force acts upon internal slides that are part of the inner shaft; these slides transmit the force that holds the drive key in its engagement slot of the outer housing.

Torque Limiting Engagement & Disengagement

When the torque load exceeds the rating of its precision tempered torque springs, the Torq-Tender’s drive key pivots out of the engagement slot to disengage the device. When disengaged, the torque limiter does not provide significant resistance to rotation.Upon completing one shaft rotation, the torque limiter will automatically attempt to reengage. Once the overload is removed and speed is reduced, the drive key will snap back into the engagement slot, and the Torq-Tender will be reset for the subsequent incidence of overload.

Custom Torque Limiters

If you’re in the market for a fully-customized torque limiter coupling, Zero-Max offers many custom options for your direct application requirements. From special materials to unique environmental requirements, our engineers have experience designing a special unit to meet your needs. Zero-Max is a trusted provider and manufacturer of precision torque limiter products. We provide custom solutions for various industries and applications, including packaging, automation, specialty machines, and more.Torque Limiter Coupling Industries Served

At Zero-Max, we designed our Overload Safety Devices to deliver dependable overload protection. Select an application example below to explore industry-specific uses and benefits.Inline Torque Couplings for Packaging Machinery

Zero-Max motion control components help users increase output and profitability by improving the performance of packaging machinery. Our overload safety couplings can be designed for any application, from wash-down and corrosive environments, to those requiring special features and operation.Torque Limiters for Specialty Machine Components

Zero-Max’s overload safety couplings are an ideal fit for the unique challenges of specialty machine applications. We offer in-house design, testing, and production services to meet your custom motion control component specifications.Contact Zero-Max to Discuss Your Torque Limiter Coupling Needs Today

Zero-Max is your trusted source for precision power transmission products. For more information on custom or standard inline mechanical torque limiter couplings, contact us or click here to find your local sales representative. With several standard and custom models to choose from, we have a torque limiter to suit your needs.