Innovative Solutions to Wind Turbine Applications

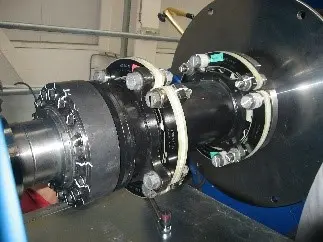

Zero-Max is a trusted and approved designer and manufacturer of driveline products for the global wind turbine industry. Based on our decades of experience designing coupling solutions for the most demanding industrial machinery, we understand the special requirements of this dynamic industry.

Zero-Max offers field-proven solutions for wind turbines that are designed to deliver maximum performance, quality, and reliability. Our wind turbine couplings and torque limiters provide the highest level of overall protection for the extreme wind and changing climate conditions that are common in wind turbine applications. The intelligent design of Zero-Max's rugged and reliable solutions require little to no maintenance and are ideal for both original installs and for after-market upgrades/replacements.

Zero-Max Wind Turbine Coupling Benefits

- Wind turbine couplings designed and engineered by up-tower professionals

- Couplings and Torq-Limiters available for many turbines

- Stock of popular models for short to immediate turnaround

- Manufactured to ISO 9001:2015 quality standards

- Proven, Robust and Available

- Lower life cycle cost (LCC)

- Ideal for wind turbine use in difficult power grid conditions

- Maintenance free with consistent and repeatable operation

Below is a listing of field-proven solutions that Zero-Max can supply for new installations and after-market upgrades/replacements:

| Turbine MFG | Turbine Model | Coupling | Torque-Limiter* | NOTE** |

|---|---|---|---|---|

| Acciona/Nordex | AW-1500 | X | X | |

| NEG Micon/ Vestas | NM44/NM48 | X | ||

| NEG Micon/ Vestas | NM52/NM54 | X | ||

| Pioneer Wincon | P750/49 | X | X | |

| RRB Energy | PS600 | X | ||

| Siemens-Gamesa | G47 | X | ||

| Siemens-Gamesa | G5X | X | X | |

| Siemens-Gamesa | G8X/G9X | X | X | GEN2 & GEN3 |

| Siemens-Gamesa | G114 | X | X | 50 Hz Only |

| Unison | U88/U93 | X | X | |

| Unison | U113 | X | X | |

| Vestas | V47 | X |

* Zero-Max Torque Limiter designed to work in conjunction with Zero-Max coupling. In most cases, the Torque-Limiter is provided standard with coupling solution.

** Replacement Disc-Packs available for other models.

.jpg)