Flexible Shaft Couplings

Zero-Max is an industry-leading shaft coupling manufacturer. Our zero-backlash Flexible Shaft Couplings handle large shaft misalignments without causing high radial stress and perform better than other flexible or rigid alternatives in high-performance applications. Passion, Quality, Service, and decades of experience and expertise went into designing each of our product lines. The results are components that deliver:

|

|

High-Performance Flexible Shaft Couplings from the Industry Leader

Our Proven Designs Help You Achieve Optimal Performance

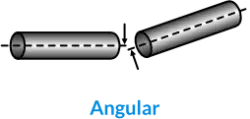

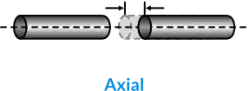

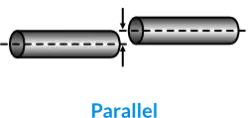

Shaft misalignment can limit a machine’s performance, cause excessive vibration, create high reaction loads and accelerated wear, and often leads to premature equipment failure. Flexible Shaft Couplings can help prevent these issues by transmitting torque while compensating for parallel, angular, and axial misalignment between drive components. When installed correctly, zero-backlash couplings can reduce vibration, minimize noise, and protect drive shaft components which can increase both performance and lifespan.We offer Flexible Shaft Couplings in various models and styles, including a series specifically designed for servo motor, automation, and wind turbine applications. You can also request custom designs engineered to meet your unique application requirements. View our catalog.

Composite Disc Couplings

Precision CD® Couplings are engineered and built to withstand the rigors of the most demanding servomotor systems. High torsional stiffness and zero backlash operation delivers repetitive reversing, stopping, indexing, and high cycle rates. Available CD Coupling models include:ServoClass® Flexible Shaft Couplings

These zero-backlash precision metal disc-style couplings offer high torsional stiffness and superior misalignment capacity while helping to reduce reaction loads on connected components.Control-Flex Shaft Couplings

These zero backlash flexible shaft couplings are engineered to ensure accuracy on encoder and other feedback devices and feature clamp-style hubs for a superior, secure, and vibration-resistant shaft connection. The Control-Flex Shaft Coupling flex elements offer ultralow bearing reaction loads caused by shaft misalignments.Schmidt Couplings

This line includes models for large shaft offsets or inline shaft applications with smaller shaft offsets. Schmidt Couplings are uniquely designed to handle applications with challenging misalignment issues or large fixed or variable shaft offsets.Easy-to-Install Flexible Shaft Couplings

Zero-Max Flexible Shaft Couplings form a secure connection between drive and driven components. Once installed, our shaft couplings provide maintenance-free operation. Additionally, our couplings can easily be connected and disconnected for inspection as needed. The proper tightening torque and additional installation information for Zero-Max’s selection of flexible shaft couplings can be found in our Product Installation Guides.Required Flexible Shaft Coupling Installation Components

Flexible shaft couplings typically require the following components:- Calibrated Torque Wrench

- Hex Socket Set / OR / Open-End Wrench** for Coupling Bolts

- Shaft Alignment Tools

- Cleaning Cloth

- Caliper

Flexible Shaft Coupling Considerations

Flexible Shaft Couplings provide torque transmission while helping to improve machine performance and life, but using a low performance coupling or the wrong type of coupling can impede mechanical performance, reduce throughput, and even cause downtime. Products that are too rigid or used outside their recommended ratings can create excessive bearing loads that can impact performance and lifespan. Options with backlash or that “wind-up” (low torsional stiffness) with changing speeds and/or directions limit a machine’s operating speed and throughput.Primary considerations for selecting a Flexible-Shaft Coupling include torque capacity, torsional stiffness, motion profile, shaft sizes, and the type and amount of shaft misalignment possible. Keep in mind that often misalignment is induced over time as compents wear or machines settle.

Additional considerations include:

- Continuous and Peak Torque Requirements and/or Motor HP

- Maximum Coupling RPM

- Distance Between Shaft Ends (DBSE)

- Service Factor

- Misalignment Requirements

- Physical Space Limitations

- Hub Bores, With or Without Keyways

- Any Environmental Considerations

How to Choose the Right Flexible Shaft Coupling for Your Application

To select the proper coupling size, identify the application’s requirements for torque, rpm, misalignment, and service factor. Be sure to choose a Flexible-Shaft-Coupling with performance and mounting options suited for your motion profile (contact Zero-Max for any assistance required). Confirm the selected coupling’s maximum rated torque is sufficient for the application. Select a coupling size with operating torque (Tn) greater than the required torque (and service-factor). Check coupling ratings to be sure it is within the rated maximum speed and that the misalignment capability is sufficient for the use. Lastly, check to be sure that the coupling fits the required dimensions such as available space envelope and bore sizes.Selection Procedure Information

If continuous torque is known, multiply it by the required service factor to get the Design Torque:- Design Torque (in-lbs) = Continuous Torque (in-lbs) x Service Factor

- Design Torque (in-lbs) = (HP x 63,000 x Service Factor) / Coupling RPM

- Required HP = 100 at 1750 RPM and 1.5 Service Factor

- Design Torque (in-lbs) = (100 x 63000 x 1.5) / 1750 = 5,400 in-lb

Learn More About Flexible Shaft Couplings from Zero-Max

We offer a wide selection of flexible shaft couplings for high-performance applications. Contact us to discuss your application, request customization, or find your local sales representative today.