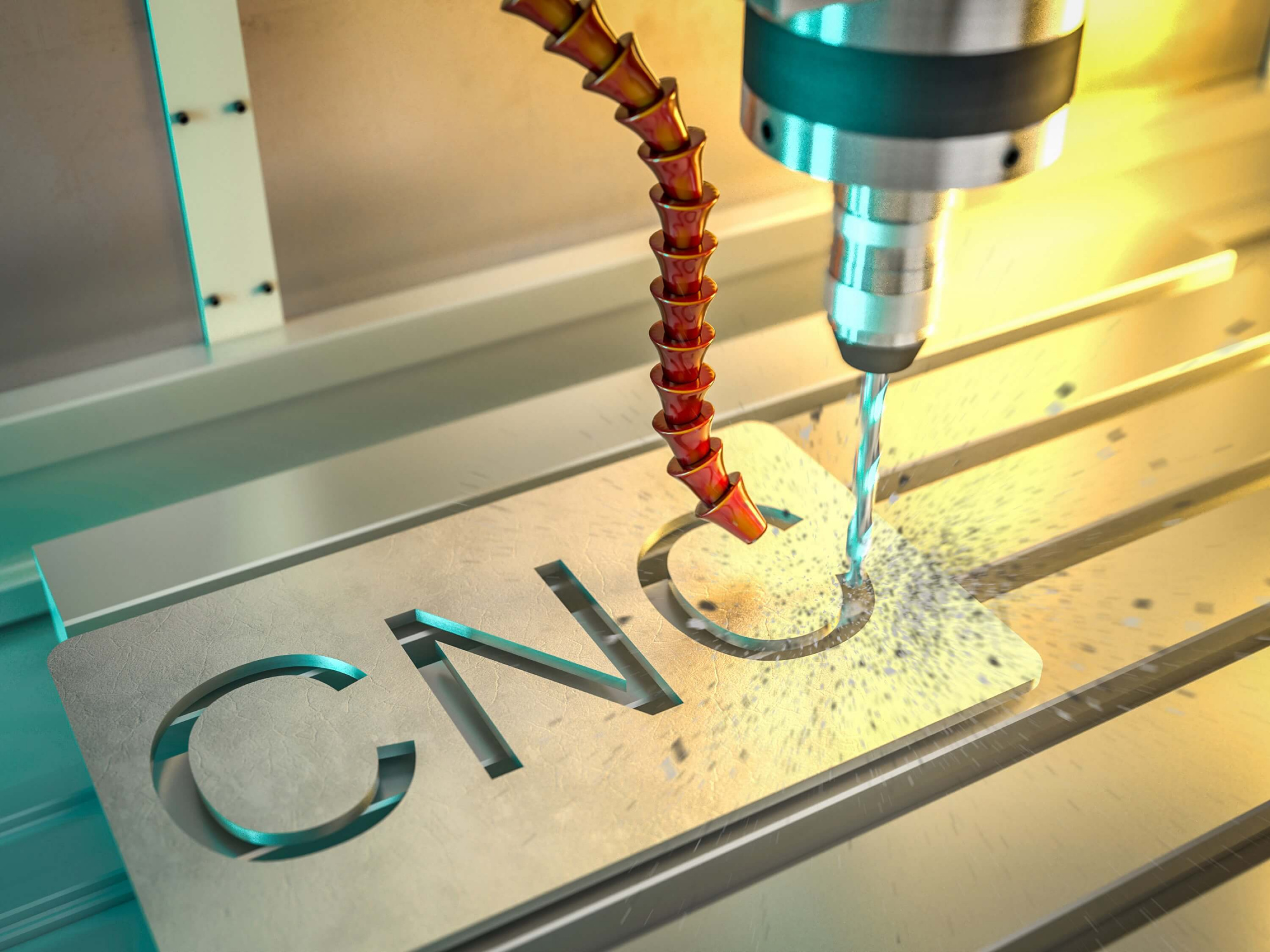

Motion Control Solutions for CNC Machine Tools

Precision Shaft Couplings, Keyless Shaft Bushings, Actuators & Gear Drives

Many CNC systems are designed for precise, continuous, unattended operation requiring consistent high-speed performance and reliable components. Zero-Max offers several lines of readily available motion control component solutions for demanding machine tool applications. Our robust, zero-backlash coupling designs are engineered to withstand the demands of 24/7, 365 operation. We offer high performance Flexible Shaft Couplings with high misalignment capacity and low reaction loads in aluminum, steel, stainless-steel, and custom material/plating options. The zero-backlash and high torsional stiffness of our shaft couplings allow for precise movement and positioning in reversing and indexing applications. Our skilled engineers can also customize a solution to meet the specific needs of your equipment and application.

View our product offering below, contact us today or find your local sales representative for more information on CNC machine tools and motion control components.

Machine Tool Solutions

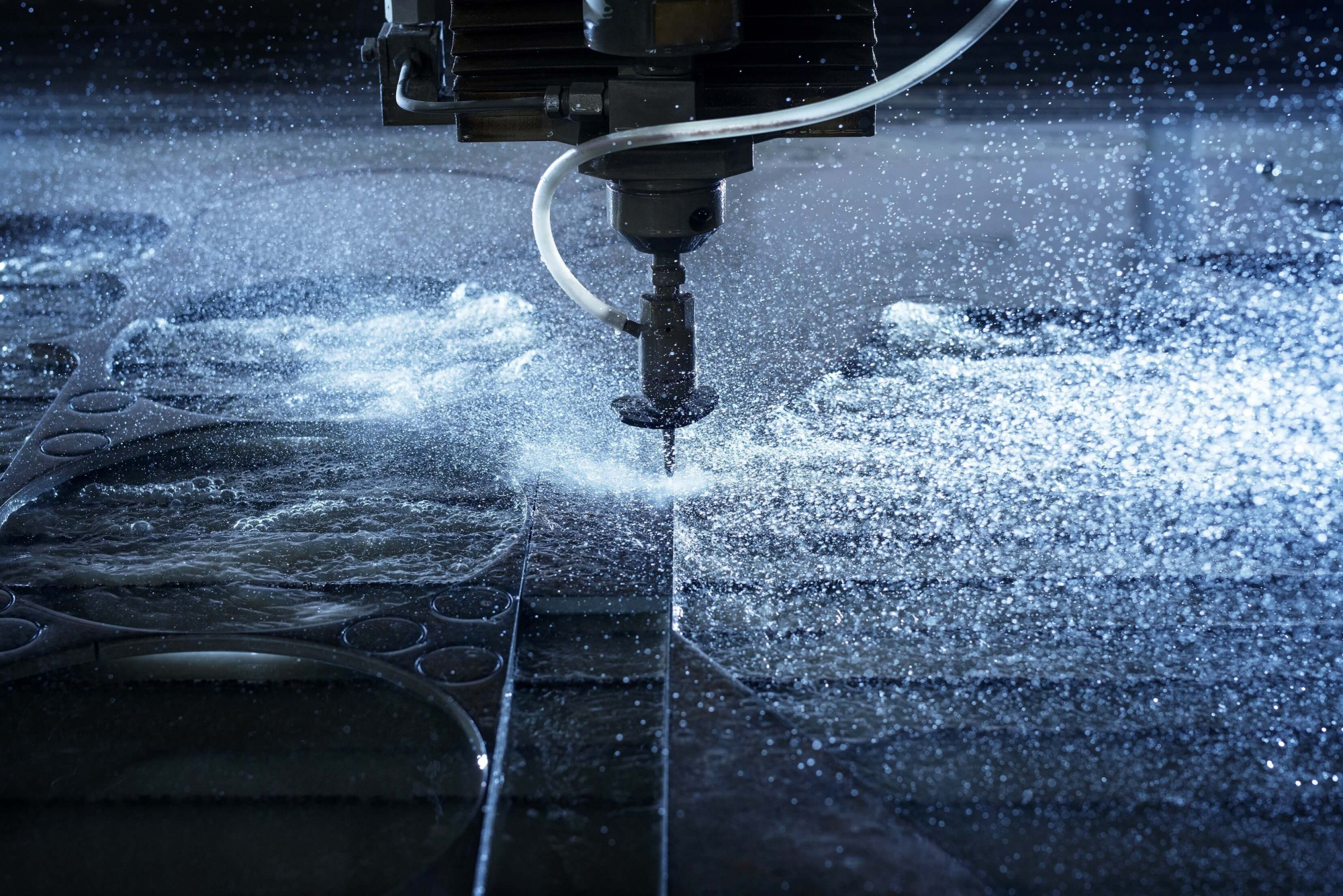

Our reputation for robust designs and field-proven reliability has made Zero-Max motion control solutions the preferred choice for machine tool OEMs and rebuilders. We can provide solutions for CNC Milling Centers to waterjet cutting machines and in applications ranging from component positioning to connecting a ball-screw to a servo motor. Our comprehensive product line includes:- CD® Couplings

- ServoClass® Couplings

- ETP Keyless Shaft Bushings

- Crown Right-Angle Gear Drives

- Roh’Lix® Linear Actuators

- Control-Flex Shaft Couplings

Learn more about our components for CNC Machines by category below.

High Precision Requirements For CNC Machine Tools

- CD® Couplings: CD Couplings allow machines to maximize output and performance in the most demanding applications. The large misalignment capacity, high torsional stiffness, and dynamic load capacity ensure reliable CNC machine operation.

- ServoClass® Couplings: ServoClass Flexible Shaft Couplings are ideal for high-speed rotary and linear actuator applications, including servo motor driven ball-screw applications. These flexible shaft couplings offer zero-backlash, low inertia, and high torsional stiffness. Available in 14 sizes in both single and double flex/disc models.

- ETP Keyless Shaft Bushings: The ETP shaft connection is infinitely phase adjustable for machine tool applications requiring ultra-precise rotary timing and linear position, extremely low run-out, fast and easy mounting, and/or frequent readjustments. ETP hydraulic-based keyless bushings precisely mount and dismount in seconds and offer hundreds to thousands of mounting cycles.

CNC Machine Tool Applications

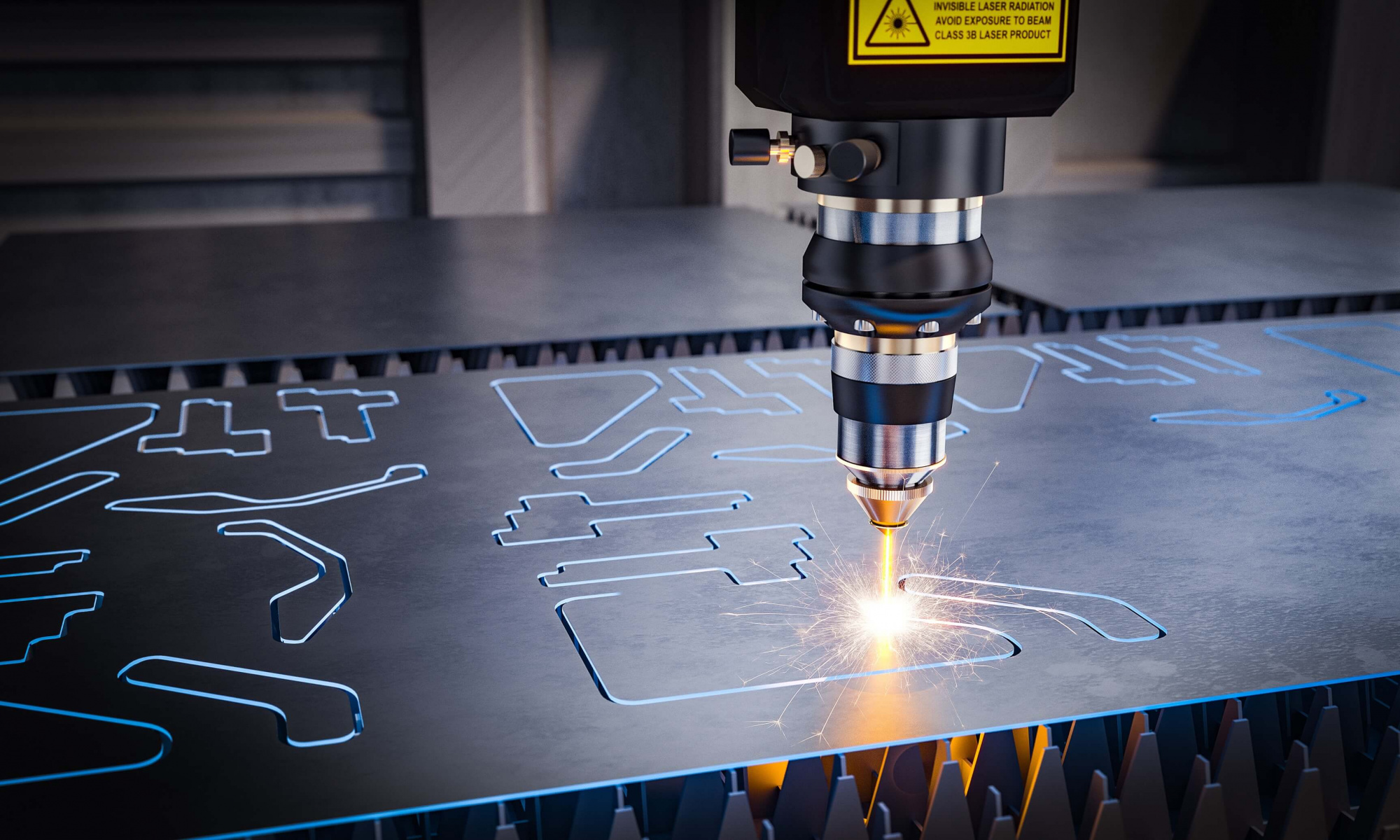

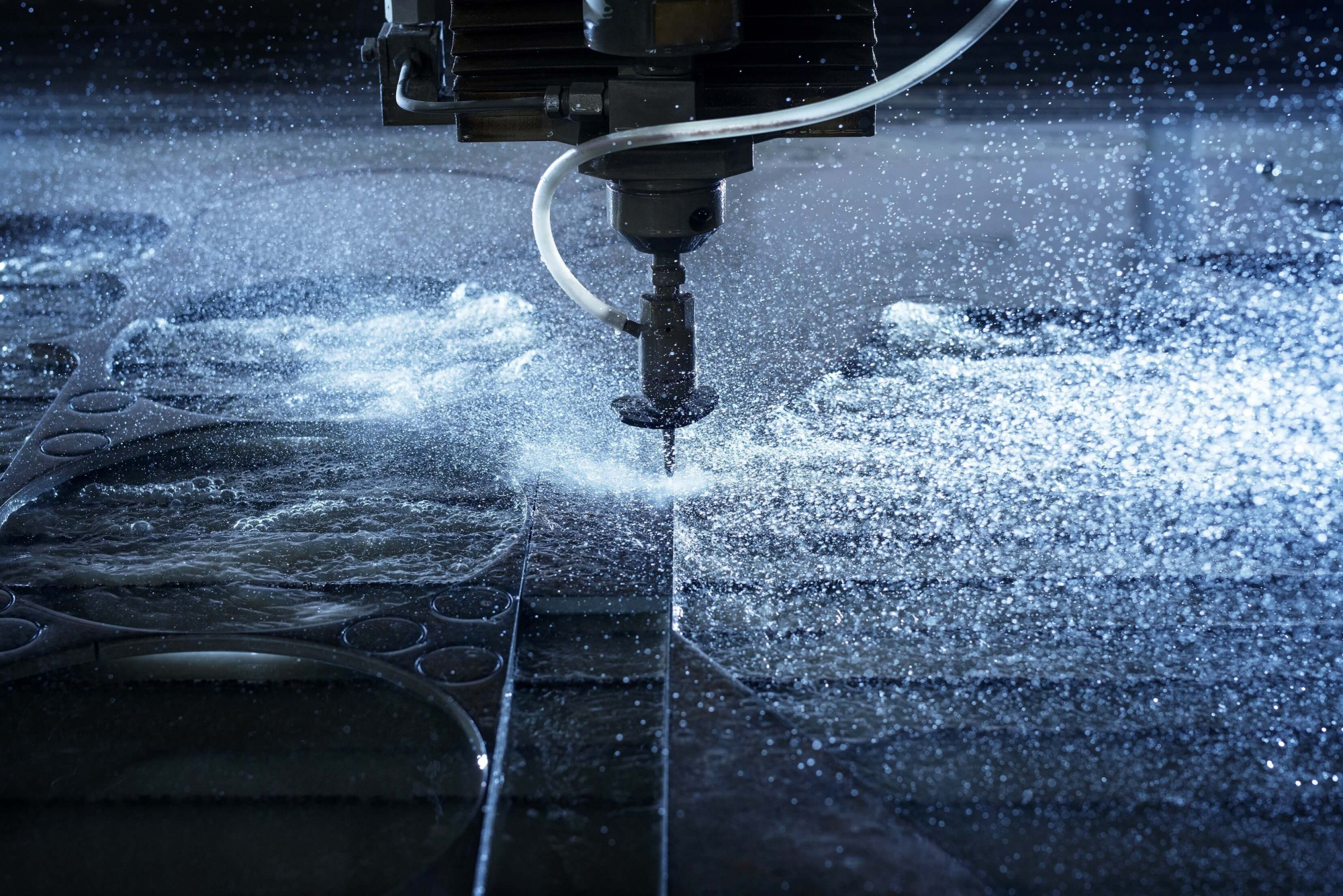

We designed our motion control components for versatility, allowing you to solve common misalignment issues and improve performance in various types of machine tool equipment. Our components are designed for use in:- Waterjet Cutting Machines

- Vertical Broaching Machines

- Laser Cutting Machinery

- CNC Milling Centers

- Other Machine Tool Equipment

Achieve Better Accuracy in Measurement Equipment

The right motion control components maintain high servo system speeds without sacrificing accuracy, performance, or positioning. Our high precision shaft couplings, right-angle gear drives, and linear actuators help resolve vibration, misalignment, and other mechanical issues to improve measurement equipment performance and durability.- Crown Gear Drives: Right Angle 90-degree Gear Boxes are ideal for changing shaft orientation from the input direction. Designed for unidirectional or reversing rotary motion or for making fine, smooth, and accurate adjustments. Ideal for low- or high-volume applications as well as those involving steep or varying planes.

- Roh’Lix® Linear Actuators: Convert rotary motion to smooth linear motion for axial loaded applications oriented horizontally or vertically. Our Linear Actuators run dry, do not require lubrication, and feature built-in overload protection for your equipment. They are available in five inch and five metric sizes for different shaft sizes and thrust capacity requirements.

- Control-Flex Shaft Couplings: Ideal for accurate measurement in feedback encoders, tachometers, and other measurement devices critical for operation. Designed to accommodate large amounts of parallel, angular, and axial shaft misalignment, with very low reaction loads on the connected shafts and equipment bearings.

The Preferred Choice for Machine Tools

Accuracy, high misalignment capacity, low reaction loads, and reduced vibration are all benefits our flexible shaft couplings provide for machine tool equipment. Although there are many options for connecting a servo motor to a ball screw, engineers consistently choose the reliability and high performance of our high precision motion control solutions. Our shaft coupling solutions provide zero backlash and high torsional stiffness. This allows for more precise movement and positioning that is critical for CNC machine tool applications. With extensive inventory and complete in-house machining capability, we can also provide short lead times on both standard and custom designs.

Custom Solutions for Rebuilding Machine Tools

Machine tool rebuilders typically have specialized requirements for upgrading or modernizing older equipment. When a standard solution may not be perfect, choosing Zero-Max to customize a component for your machine rebuild is the right choice. Our engineering team offers complete design assistance and can tackle any motion control challenge. Send us your application requirements, and we will design a high-precision, custom component that meets your needs, for any quantity, and with quick turnaround.- Custom Dimensions

- Higher Torque Requirements

- Unique Misalignment & Mounting Demands

- Special Materials or Plating Requirements

- Housing Modifications

- Threaded Shafts & More

Contact Zero-Max For CNC Machine Tool Components

For more information on the various machine tool components available, contact us or find your local sales representative.