Crown Gear Right Angle Gearbox

Zero-Max provides high-quality and flexible 90-degree gearboxes to suit various applications. We carry a full range of sizes, as well as IP65-Rated Crown Gear Drives, from stock. View our selection below and contact us with any questions. Additionally, request a quote for more specific requirements.

Crown Gear 90 Degree Gearbox Features and Options

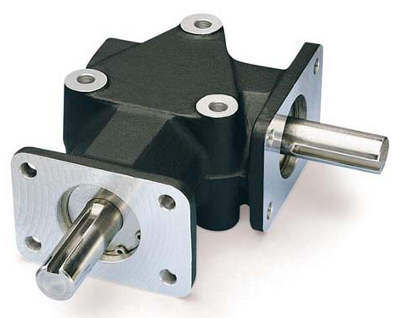

All Crown Gear 90-degree angle gearboxes are designed for maximum performance, strength, and heat dissipation. The curved teeth of the premium spiral bevel gears provide increased torque capacity and reduced vibration and noise at high speeds. The enclosed design offers smooth and quiet operation, ensuring the internal gears remain aligned and free from debris contamination. The aluminum housing maximizes heat dissipation during operation. Crown Drives are available with shafts of 3/8, 1/2, 5/8, and 3/4 inch diameter in either two-way or three-way units, with 1:1 and 2:1 ratios, and support speeds of up to 2,000 RPM. Three-way units are also available with 1-inch shafts. Additionally, we can accommodate unique and custom requirements. The available Right Angle Gearboxes offered by Zero-Max include:

- Standard: Black anodized aluminum housing, non-magnetic stainless steel shafts

- IP65-Rated: Nickel-plated aluminum housing, non-magnetic stainless steel shaft seals, food-grade grease

Differentiating Crown Right Angle Gearboxes

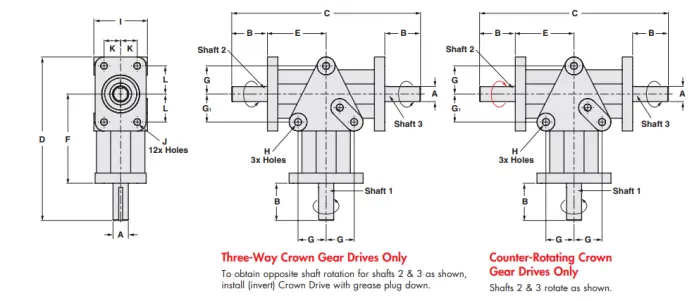

Zero-Max Crown Gear Standard Right Angle Gearboxes are offered in two- and three-way designs as well as a counter rotating design positioned to create a 90-degree transfer of power transmission. Right-angle gearbox drives are ideal for applications with limited space and where the driven equipment needs to be in close proximity. Two-way drives offer a single output shaft (“L”), whereas three-way drives offer an additional output shaft (“T”) which allows changes in axis rotation. Standard counter-rotating Crown Right-Angle Gearboxes are designed with two output shafts that rotate in opposite directions, creating an ideal counterbalance.

IP65-Rated Right-Angle Gearbox

IP65-rated Miter Gearboxes are ideal for food-related applications or other applications requiring washdowns. Our IP65-Rated right angle gearboxes are tested for IP 65 Ingress Protection against dirt and water jets and feature nickel-plated aluminum housings that are permanently lubricated with H1 rated food-grade grease. Specific applications requiring IP65-Rated Right Angle Gearboxes include:

- Food Processing Equipment

- Ovens & Dryers

- Packaging Equipment

- Test Equipment

How to Select Your Crown Gear Right Angle Gearbox

Following this process will help you select the appropriate right-angle transmission gearbox for your application.- Determine your preferred input/output ratio. Standard ratios are 1:1 and 2:1. It is also possible to use a step-up ratio of 1:2 by using shaft #2 as the input shaft on 2:1 units.

- Designate which shafts are to be input and output shafts. This step is crucial to determine that no shaft will turn faster than 2000 RPM. If shaft #2 in the 2:1 ratio models is selected as the input shaft, it can turn at a maximum of 1000 RPM. In the 1:1 ratio models, it makes no difference. However, the choice, in either case, will affect your mounting.

- Choose drive type. Use either a 2-way or 3-way configuration.

- Choose style. Determine if a Standard Model or IP65 Ingress Protection / Nickel-Plated Model is desired.

- Select the correct model number. Select the valid model number based on the above selections. Note: units with 3/8 inch shafts have flats, and units with 1/2, 5/8, 3/4 and 1-inch shafts have standard keyways. Also, 1-inch shaft models are available in 3-way type only.

- Ensure that the designated output shaft has a torque capacity higher than your application's load. Be sure to apply the appropriate service factor.

- If your application requires modification of shafts or housings, send a drawing and a description of the application to the factory.

90 Degree Gearbox Applications

The right-angle design of 90-degree gearboxes and the ability to provide high-performance power transfer ensure their use in many industries and applications. Crown Gear 90 Degree Gearboxes are often ideal for Specialty Machine and Automation Machine applications because of their reliability and efficiency. Additionally, they operate smoothly to offer a quiet performance without compromising torque capacity. Additional applications of Zero-Max Right Angle Gearboxes include:

- Conveyors, robotic arms, automated welding, assembly equipment, and printing presses in manufacturing

- Mining, cement, steel, and pulp & paper manufacturing in heavy industry

- Agricultural farm machinery equipment

Why Zero-Max for Crown Gear Right-Angle Gearboxes

For over 75 years, Zero-Max has been an industry-leading provider of motion control and power transmission solutions. We are committed to providing the highest quality and excellent service for even the most demanding applications. We offer a wide range of right-angle gearbox sizes, and our Crown Gear brand gives the most dependable transfer of power on the market. In addition, our qualified team of engineers can create unique customized 90-degree gearboxes to handle any specific need. No application is too unique or demanding for us, as we offer innovative designs and premium products manufactured using state-of-the-art technology.

Contact Us for Your Right-Angle Gearbox Needs

With the most dependable right-angle gearboxes on the market today, request a quote for any of your needs to ensure smooth and efficient operation. Contact us with any questions or find your local sales representative to find the right 90-degree gearbox for you!