Zero-Max News

Winds Of Change Are Blowing For Couplings – Modified Zero-Max CD Coupling Solves High Performance Requirements in Wind Turbines Designed By NEG Micon

Jun 01, 2009

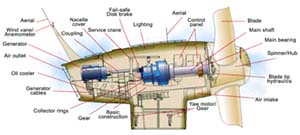

Minneapolis, Minnesota: The coupling needs for wind turbines pose problems that are beyond the performance specifications of most standard coupling offerings. And no wonder. Wind generators are big - really big.They operate at varying speed ranges from 12 rpm to 22.5 rpm driving a generator at speeds between 1000 and 1800 rpm. They are subject to constantly varying wind forces and climatic changes.

Blades for these behemoths are over 115 feet long and weigh over 7-1/2 tons each. The distance from blade tip to blade tip is 204 feet -- about the length of the wing span of a 415 passenger 747 airplane. The turbine generator system is positioned as high as 262 feet in the air, completely isolated from routine observation and maintenance. The entire system of propeller, shaft, gears, coupling and generator is designed and built to function continuously without failure for a projected twenty years plus. All this while being subject to changing climate conditions from sub-zero cold to extreme tropical heat. (Photos One, Two and Three)

|

|

|

Wind turbines like this new design from NEG Micon tame the forces of nature by transforming them into controllable energy. The company says that it is very conscious of the visibility of its products in the landscape and strives to find a simple and aesthetically pleasing design, which fits well with its surroundings. |

Two workers inside turbine generator housing show relative size and enormity of the system. |

|

|

Zero Max CD Coupling used in the NEG Micon wind turbines. The largest version for the 2000kW turbine weighs nearly 300 lbs while the smaller version for the 900kW weighs about 150 lbs. Hubs and shaft components are precision machined of steel. Patented disc packs are made of a special composite material. |

But as power from the wind has become an important energy source, since it is renewable, non-polluting and is price competitive with traditional energy sources, it has become a very successful emerging technology. Wind power is the fastest growing source of electricity generation. It now supplies enough megawatts in the United States alone to meet the needs of 2 million households annually.

Led by Denmark-based NEG Micon, a world leader in wind turbine manufacturing, wind farms are being designed and built throughout the world. Originating twenty years ago in Denmark, large wind farms now are operated on five continents, including in the United States in California, Iowa, Minnesota and Wyoming. Concentrations of these wind farms have developed in Iowa, Minnesota, Texas and Colorado, and now claim a 15 percent global market share which continues to grow rapidly.

Lower Cost Energy Needs Drive Wind Turbine

Designs Including The Coupling Requirements

The problem with wind power in the 1980's when it became a serious energy alternative was that it cost twice that of conventional electric power. Now, thanks to favorable legislation encouraging its development and technological advances made by NEG Micon and component suppliers like Zero-Max, wind energy is on a comparable price level with coal and nuclear sources. The competitive price feature, plus the zero-emission, non-polluting and renewable advantages, is behind wind energy's recent rapid growth.

To reach a price competitive level, NEG Micon invested heavily in wind turbine designs that lowered the cost and maximized the energy production. Turbine size was increased dramatically with recently installed turbines delivering up to 2000 kilowatts. One of these giant wind turbines generates enough energy to service the needs of 300 average homes for a year. And as the turbine designs have grown in size along with their energy output, the drive systems have become larger, more sophisticated and more efficient.

|

|

Wind turbine drive train consists of three driving blades connected to the low speed shaft of the gearbox while the high speed shaft connects to the Zero-Max CD Coupling and the turbine generator. |

Oscillating Loads Transmitted To Coupling

A key component in wind generator drive systems is the coupling, which connects the high speed gearbox shaft and the asynchronous generator. The gearbox is mounted on rubber bushings that absorb the changing forces transmitted by the wind through the system. These movements -- generated by heavy oscillating aerodynamic loads relative to the generator -- are transmitted and are absorbed by the couplings. NEG Micon required a coupling design, which would not only handle these loads but would do so over years of continuous service with little or no maintenance.

"NEG Micon examined and tested many different style couplings to see which would work best," reported Brian Onkst Sr., design engineer for Zero-Max. "They originally focused on elastomeric coupling designs because they had the flexibility to absorb the oscillating loads. The problem was they didn't have the long-term durability needed for years of operation without component replacement."

"NEG Micon then examined the Zero-Max CD® coupling which at the time wasn't available in a large enough size to accommodate wind turbine designs. They liked the fact that the coupling had high misalignment capability and also substantial vibration and shock control features along with a material design which could stand up to all weather elements. We partnered with their engineers and we developed an appropriate design in the correct size. We tested prototypes which led to the present models in use."

The CD coupling used in the NEG Micon NM2000 turbines is a customized larger version of a standard model. Using two disc packs in a spacer coupling configuration, the hubs mount on the 150 mm diameter shafts. The overall disk diameter is 460 mm with a coupling length of 578.5 mm. The CD coupling used in NEG Micon's NM 900 turbine has a 110 mm shaft diameter at the gearbox end and a 100 mm shaft diameter at the generator end. Overall disk diameter is 348 mm while the coupling's overall length is 440 mm.

The CD coupling discs are bolted to the coupling's exterior mounting hubs and a steel centering shaft. The disc pack's patented, open arm design, together with the composite material that it is made from, are the keys to the coupling's ability to handle the oscillating loads in the wind turbine application.

|

|

Patented open arm disc design provides high misalignment capacity along with a high degree of rigidity. The coupling has superior damping and isolation of shock and vibration loads features. Disc packs resist corrosion fretting at bolt hole locations. |

The innovative, open arm disc design and rugged composite materials provide high misalignment capacity found in many elastomeric couplings but with higher torsional stiffness. In most applications, the open arm disc allows up to 0.040" (1mm) parallel misalignment and up to 3° angular misalignment. The composite material has a ply or fiber orientation to it which gives it rigidity and also dampens shock.

Early in the turbine design process, NEG Micon engineers had to modify the distance between gearbox and turbine generator by 100 mm. This necessitated reducing overall length of the coupling by an equal distance. Using a linear variable displacement transducer (LVDT), they determined misalignment conditions present. However, the required change added approximately 20 percent more misalignment(stress) to the discs in the coupling. Misalignment went from 1° to 1.2°. But because of the CD Coupling's high misalignment capability, upon testing the modified version, the discs handled the added stress with no signs of fatigue.

"The eight bolt disk pack configuration was very well suited for NEG Micon's application," reported Onkst. "The disc pack provides the misalignment capability for these wind turbines without requiring an overly large design configuration to handle the oscillating loads. This saves space, reduces overall weight and is more economical. The composite material of the disks stays rigid over time and doesn't soften like elastomeric couplings. Also, the damping feature of the composite discs promotes quiet operation which is very important in these systems."

Coupling Is Environmentally Tough

The Zero-Max CD Coupling was designed to provide chemical and moisture resistance in hostile environments too difficult or impossible for elastomeric and steel disc couplings. In the NEG Micon application, fluctuating weather conditions including winter and summer extremes haven't effected the couplings. All have operated continuously for over one and a half years without maintenance. According to NEG Micon's engineers, the coupling is visually inspected and bolt tension checked during routine service of the turbine. No service was required of the couplings as a result of these inspections.

Fretting corrosion to the discs, especially around bolt locations, often is a problem in steel disc couplings, especially where intermittent torque is experienced. In the NEG Micon application with the CD Coupling, no sign of fretting corrosion occurred in the one-and-a-half years of testing.

Future Wind Turbine Couplings

Larger wind turbines are in the offing, especially for offshore installation on the open seas. These, according to NEG Micon, will operate at similar speeds as current turbines which utilize the asynchronous generators but at higher torques. Equipping these larger turbines with CD Couplings should prove as successful as current turbines, according to Zero-Max design engineers, because the disc packs can be modified easily to handle higher torques. (Note: CD Coupling disc packs are produced using laser cutting instead of stamping dies. This makes the disc design configuration easier to modify since no hard tooling is used saving both time and money).

In addition to wind turbines, these large CD Coupling designs have application in large commercial workboats, off-high vehicles, paper converting machines, printing presses and mining equipment.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.