Zero-Max News

Customized Zero-Max CD® Coupling Ensures Zero Positioning Error Of Die Cutting And Printing Stations In The Latest Mark Andy High Speed Label Printing System

Sep 01, 2009

Chesterfield, Missouri: Die cutting stations and print stations in the LP 3000 new model high speed label printer from Mark Andy, Inc. utilize the latest servo drive and coupling technology to ensure zero print error from coupling deflection while the system operates at 750 feet a minute.

The Model LP 3000 label printer from Mark Andy, Inc. produces high quality labels and can print two sides in a single pass along with die-cutting, punching, perforating, sheeting and folding of high quality labels for cosmetic, pharmaceutical, wine and similar consumer products. These Mark Andy printing systems maximize productivity and achieve consistent quality due largely to their robust design which incorporates the latest servo drive and innovative coupling designs.

|

|

|

Merritt PMI vertical veneer slicer produces up to 90 sheets of high quality wood veneer per minute (slicing speed). |

The veneer slicer utilizes Zero-Max CD® Couplings which provide motion control of high torque and high reverse loads in the system. |

Smooth operation of the die cutting stations in the Model LP 3000 is especially critical because it is synchronized with the print stations. Spikes in torque generated during the die cutting cycle can throw off the registry to the print stations. Maintaining stiffness (registry) during these torque spikes is job one for the coupling.

"Because of the accuracy required and the high torque loads of these die cutting stations, we evaluated many different couplings," reported Bill McCroskey, senior project engineer for Mark Andy. "Bellows and spiral cut couplings just weren't robust enough. Solid couplings couldn't handle the misalignment requirements. On the gearbox driven models LP 3000 and 2200, the biggest problem was the constrained envelope into which the coupling had to fit. We needed a coupling which was large enough to handle the torque loads but sufficiently small to fit in the tight area between the die cut roll and the gear box where the coupling connection was made."

|

|

|

Re-engineered version of the Zero-Max 6P30C CD coupling is just 1.60 inches wide and fits between the die cut roll and the gear box. The coupling absorbs torque loads, enhancing die cut accuracy and print registration quality. |

|

Mark Andy uses standard Zero-Max couplings in the printing stations of several of its print systems including ones with servo motors. However, for the die cutting stations in the model LP 3000 and 2000 systems, while a standard model CD Composite Disc model was a good choice for its torque rigidity and misalignment features, "size was the problem," said McCroskey. "There wasn't a standard CD coupling that would work in that small area."

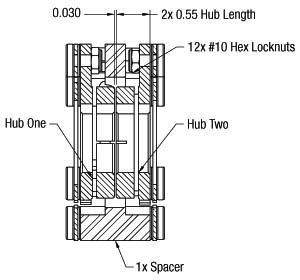

Zero-Max design engineers came up with a solution – a re-engineered version of its 6P30C CD coupling. This standard version is a double flex model with two center disc packs and clamp style connecting hubs. The re-designed model reverses the two outside connecting hubs so that they face inward instead of outward. Also, the two disc packs are located on the outside of the coupling instead of at the center. This new coupling configuration is designed so that all components nest snugly together and the coupling's normal width for that model is reduced over 50 percent from 3.92 in. to just 1.60 in. This reduction in size doesn't compromise the coupling's performance in the system. It enhances it.

"Since the rotary die cutting cycle is intermittent and timed to the print station cycles," reported McCroskey, "the repetitive torque spike from the die cutting module has to be controlled so as not to disrupt the printing cycles and print registry. The specially designed CD Coupling does that. Just as important, the coupling contributes zero positioning error downstream in the system so all modules stay in sync and print register and quality is guaranteed without any operator intervention or tweaking of the system while operating at top speed. The coupling keeps the intermittent motion under control while turning at 727 rpm with web label material feeding through the system at 750 feet per minute. It provides the needed torque rigidity, absorbs the torque spikes, and maintains the required positioning accuracy.

CD Coupling Composite Disc Design Helps

Ensure Zero Positioning Error In The Mark Andy System

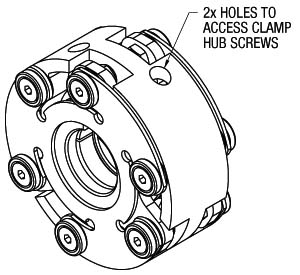

These coupling disc packs are similar in design to the standard CD® coupling models and will handle the demands required in servo systems without loss of accuracy or increase in fatigue. Other coupling manufacturers use stainless steel for their flex disc members and are more vulnerable to high stresses commonly found in servo applications. The flex discs in the Zero-Max CD® couplings are made from high tech composite material and the patented unique open arm design that enable the CD® coupling to perform at these exceptional levels. The CD® is perfect in demanding servo applications in space-constrained mechanical applications as seen on the LP 3000. (Illustrations One, Two and Three)

|

|

|

|

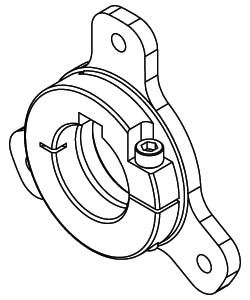

Side and three-quarter views show hub and disc pack positioning. Clamp style hub shown in Illustration Three allows for easy, top down positioning and tightening. Unique disc pack design provides flexibility, misalignment and long life while absorbing torque loads. |

||

(Editor's note: While reversing hub and disc components in a coupling to reduce space requirements is not new, it is a unique twist in the evolution of the CD coupling).

Operating specifications for this special CD® coupling are: 450 in. lbs. (50.8 Nm) continuous torque rating; 900 in. lbs. (101 Nm) peak torque rating; 2,200 in. lbs./deg (14,242) Nm/RAD); 1.25° maximum angular misalignment; 0.025 in (0.63 mm) maximum parallel misalignment; 0.035 in. (0.89 mm) maximum axial misalignment.

As for installation, McCroskey said the special CD coupling model with clamp style hubs was very easy to position in the tight work envelope. "The coupling accommodates minor misalignments nicely so all we do is position it, torque it up and it's ready to go. No special alignment tools are needed, and once in place, it never needs maintenance."

For more information on Mark Andy, Inc. narrow web printing and converting presses, call 636-532-4433. Email to info@markandy.com Website: www.markandy.com Fax: 636-532-1510. Or write to Mark Andy, Inc., A Dover Diversified Company, 18081 Chesterfield Airport Road, P.O. Box 1023, Chesterfield, MO 63006-1023.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.