Applications for Zero-Max Motion Control Devices

New Blue Falcon Screen Printing System Utilizes Innovative Zero-Max CD® Coupling To Handle 2,000 In /Lb Torque Loads

Greenville, South Carolina: Servomotor powered indexing print stations in high speed screen printing systems require accurate registration as they index, position, print and advance to the next printing stations. You see the results everywhere – high quality multi-colored images of logos, messages, pictures of animals and faces on textiles such as T-shirts, sweat shirts and other garments.

|

|

| Progressive Machine's Blue Falcon screen printing system features smooth, high speed operation with machine tool quality and durability. It accurately prints fabrics in up to 20 colors. | |

|

|

|

|

|

Garment fabrics screen printed with multiple colors and fine detail. |

|

There's no limit to the image complexity, color and overall quality detail these machines can print due to advances in the motion systems designed into these automated screen printers. When equipped with Zero-Max CD® couplings, these new servo driven screen printers index and position accurately from station to station where images are printed with remarkable consistency and repeatability. Most notable is Progressive Machine of Greenville, South Carolina which has made a quantum leap with new technology designed into its Blue Falcon screen printers. Available in several formats, these systems start with an 10 color 12 station model and range up to the largest, a 20 color 22 station model.

High Speed Servo Glide™ Technology Increases

Production Rates, Produces Quality Images

The Blue Falcon screen printers feature digital control of the indexer function and positioning. The system is designed for continuous duty operation with the indexing table movement and number of stations programmable via the operator interface. Once programmed, the system is designed to operate continuously without operator intervention. To achieve the needed smooth, repeatable operation and indexing required, top-notch engineering design is required of the motion system.

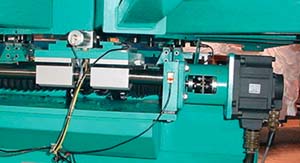

Controlling the motion each time these machine indexes is a tall order because the torque load is typically between 1,500 and 2,000 lbs. and the accuracy requirement for print registration is .002 inch. To handle these requirements, Progressive Machine design engineers, chose a single HC-SFS352 Mitsubishi servo motor (37 ft/lbs) and connected it to the precision ball screw with a Zero-Max CD model 6A37–AC coupling.

|

|

|

Note location of Zero-Max CD coupling which directly connects the servo motor to the precision ball screw. Assembly time takes under 10 minutes using the couplings clamp style hubs with a single mounting screw. |

|

This aluminum coupling design features lightweight, low inertia hubs ideal for servo motor applications. This motor assembly combination produces the indexing and print station positioning function. Turning at up to 2,000 rpm, the assembly (servo motor, coupling and ball screw) is subjected to very rapid acceleration/deceleration each time it cycles. The combination of the three components produces ample horsepower and torque without heating up or overburdening itself.

Intermittent Motion Controlled By Zero-Max CD Coupling

The Zero-Max CD coupling is a very critical component in the motion system and eliminates any backlash tendency when the servo motor starts and stops. Alignment guides assist in the positioning function and are dependent on the positioning accuracy of the drive system. If the alignment is off after a number of indexes, the guides become ineffective and degrades the print registration quality.

"We chose the Zero-Max CD coupling because it met the high physical demands of our Blue Falcon design and because it was cost effective," reports Tim Dunham of Progressive Machine. "Using these Zero-Max couplings, the servo index function is accurate to .002 inch. We have a zero backlash requirement – any backlash or hesitation in the cycle can cause misalignment and inaccurate printing. The Zero-Max CD coupling connected directly to the servo motor prevents backlash from occurring."

CD Coupling Has Unique Zero Backlash Design – Print Stations

Align Accurately With Each Indexing Cycle

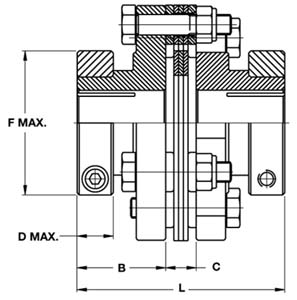

Chosen for demanding servo motor applications like the Blue Falcon, the CD coupling has most of the best features of other couplings designs with one critical difference – its patented composite disc pack design. There's nothing else like it in the coupling world. While the disc pack and coupling transmit torque similar to any conventional coupling, it does a better job of dampening backlash and shock without the coupling fatiguing which can occur in a fast-moving, high torque system like the Blue Falcon. The coupling accomplishes this through a patented unique open arm disc design made of highly durable composite disc material. This design absorbs and cushions any tendency for backlash from the servo motor's intermittent motion.

|

|

|

CD coupling disc pack from a single flex CD coupling. The couplings disc provides greater flexibility, misalignment, longer life, and damps shock and vibration through its unique patented open arm design with the use of highly durable composite material. |

Single flex CD coupling does the work of most double disc design couplings in less space and at less cost. |

The CD coupling used is a single flex, 1.50 inch (38 mm) bore, single disc model, which is less costly and does the work of most other double disc designs. It does so using less space in the drive train and with greater misalignment capability than double disc models.

While misalignment isn't an issue in the Blue Falcon system, it does make a difference in assembly time. Dunham says installation takes just 10 minutes and no special alignment tools such as lasers are needed. The coupling's clamp style hub allows for the fast installation by tightening just one screw on each of the two coupling hubs. For the Blue Falcon application, the servo motor's 35 mm shaft diameter dictated the choice of the Model 6A37-AC coupling, according to Dunham which when installed is enclosed in a protective sleeve to keep out debris.

The Zero-Max coupling proved more than adequate for the physical demands of our system," reports Dunham. "It gives us the reliable, smooth operation we need without any problems."

For more information on Progressive Machine's Blue Falcon screen printing systems, call 864-295-9697. Website: www.progressive-machine.com Or write to Progressive Machine, Inc. P.O. Box 1537, 1703-A Easley Bridge Rd., Greenville, SC 29602-1537

Servo Glide™ is a trademark of Progressive Machine, Inc.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.