Applications for Zero-Max Motion Control Devices

ServoClass® Coupling From Zero-Max Eliminates Backlash Potential In Integrated Seam Sealing Systems Couplings Connect Servo Motors To Ball Screws

Horsham, Pennsylvania: Precision sealing of integrated circuit packages at high speed requires a backlash-free motion system to produce the highest quality seal. These systems have digital sealing power that allows pulse-by-pulse control of power, giving maximum control and response to seal conditions.

|

|

|

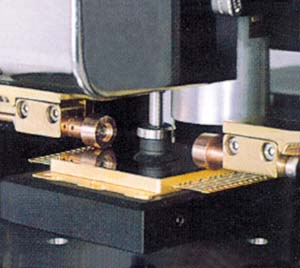

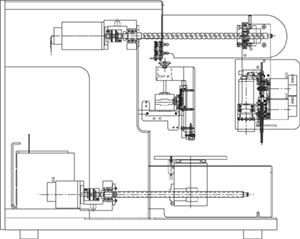

Solid State Equipment Corporation new model 2300 Auto Cassette System from precision sealing of integrated circuits. |

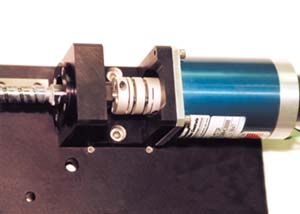

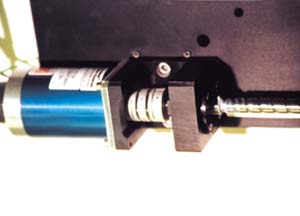

Zero-Max ServoClass® coupling connects Servo motor to ball screws. Three are employed in each system. |

|

|

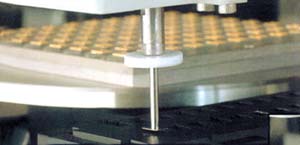

Lids are automatically picked up from lid bin tooling. The tooling can hold up to thousands of lids, and is easily changeable to handle different lid sizes. |

Solid State Equipment Corporation, a technology leader in manufacturing systems for the semiconductor and microelectronics industry, has recently introduced a new line of parallel Seam Sealers driven with servo motors.

These systems provide linear and rotary weld sealing with real time force control and automatic package height sensing for seal uniformity. Features include rotary sealing with power and speed modulation that produces superb seal fillet cosmetics and 99 plus percent yields, based on helium mass spectrometer fine leak testing and x-ray inspection. They have on-the-fly path resistance sensing to guard against arc development and programmable lid tacking to improve process repeatability. Among their users are companies like Lucent Technologies and Nortel Networks.

|

|

|

Automated lid placement and cassette handling options optimize sealing productivity and yields, for small or large lids. |

|

In designing the drive system for these Seam Sealer Systems, Ray Regan, design engineer for Solid State Equipment Corporation, decided the most effective connection of the servo motors (50 to 100 ounces/inch) to the ball screws was with a coupling designed specifically to handle the sensitivities required in a servo driven system. He chose the ServoClass® coupling manufactured by Zero-Max in Minneapolis, Minnesota.

"We looked at other couplings including those with steel, accordion type center members," reported Regan. "We ruled them out because we needed the best torsional rigidity in our servo connections in order to eliminate any possibility of backlash that could affect the Servo controls positional accuracy and dynamic stability. The specs we saw in the SC020 gave us everything we needed to accomplish that."

|

|

|

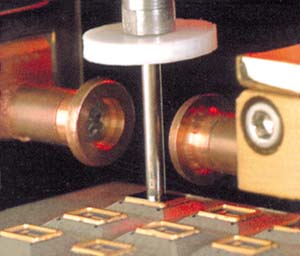

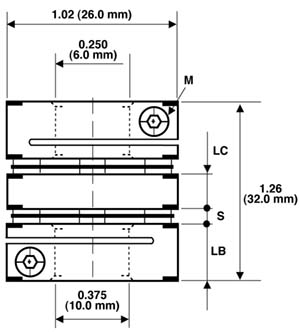

Zero-Max ServoClass® Coupling features double flex disc design. Discs are flexible stainless steel and provide high torsional stiffness and low inertia to avoid system resonance and backlash. |

The SC020 coupling can handle speeds to 10,000 RPM with operating torque of 13 in.-lb. (1.5 NM) and has torsional stiffness of 90 in.-lb./deg. (580 Nm/rad). |

Coupling Has High Torsional Stiffness And Low Inertia

The ServoClass® coupling by Zero-Max has flexible, stainless steel double discs and keyless clamp-type mounting hubs. The coupling’s design features zero backlash, high torsional stiffness, and low inertia - all issues which are critical in demanding servo driven systems.

Designed to meet the precision positioning requirements and high reverse-load characteristics of AC and DC servomotor applications, these couplings are remarkably flexible because of the double-flex disc design. It’s this design that provides the exceptional misalignment capacity and the coupling flexibility also reduces reaction loads. The result is smoother system performance and longer operating life of the connected components.

Parallel Seam Sealer Utilizes SC020 Servo Class

Couplings For Pick And Place And Positioning System

The automatic lid placing system (XY axis), utilizes three model SC020 ServoClass® couplings (.25" x 8 mm bore) which raises and places the lids for sealing. The vacuum pick and place head lifts the lid from the lid bin and accurately places it on the package using a dual optic system. One camera locates the lid position and a second camera determines the position of the package for accurate placement and tacking prior to sealing.

|

|

Providing an operating torque of 13 in.-lb. (1.5 Nm), the SC020 ServoClass® coupling operates efficiently and smoothly in the Seam Sealer System. The coupling’s torsional stiffness is 90 in.-lb./deg (580 Nm/rad) with axial stiffness of 182 in.-lb. (32 N/mm). Misalignment capacity is 0.006 in. (0.15 mm) parallel, 1.0 degree angular and ±0.013 inch (±0.33 mm) axial. Moment of inertia is 0.0103 in.-lb.2 (kgm2 x 10-6). Maximum rated speed for the coupling is 10,000 r/min. with the Seam Sealer System operating below that at its highest acceleration speeds.

|

|

|

Zero-Max ServoClass® Coupling in the Seam Sealer System provides an effective connection of the servo motors (50 to 100 ounces/inch) to the ball screws while effectively handling the sensitivities required in the servo driven system. The coupling is ideal for most digital, AC, DC, Stepper and AC synchronous driven systems. |

|

"The coupling is very durable and has no maintenance requirements once installed," reports Regan. "Once in place, we can forget about it."

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.