Applications for Zero-Max Motion Control Devices

Zero-Max CD Coupling Smoothes Intermittent Motion In High Speed Servo Powered Pouching System

Battle Creek, Michigan: Servomotor powered indexing stations in automated pouching systems require accurate registration as they position, fill and heat seal completed pouches. Case in point are the new standup pouching systems by Robert's Packaging that fill and seal stand-up pouches from roll stock at up to 220 pouches a minute with food products such as potato chips, rice, candy, nuts and pet food.

|

|

|

Robert's Packaging 100% continuous motion filling and sealing system produces 220 pouches per minute. These systems operate 24/7 and are stopped only for polypropylene film replenishment. |

Pre-printed pouches are filled with a wide range of snack and pet foods. |

Keeping motion control under control in these systems is a key machine design consideration because of the high speed, intermittent motion of the polypropylene film. Designed with a series of automated pouch forming and pouch filling stations, the intermittent motion is especially critical at the sealing station. The system's servo motor draws the pre-printed film forward through a series of rubber covered rollers, stopping to heat seal a completed pouch, restarting instantly to repeat the cycle. An indexing cycle occurs every .3333 seconds, with approximately half of that required for film advance and the remaining .1666 second used in the sealing operation.

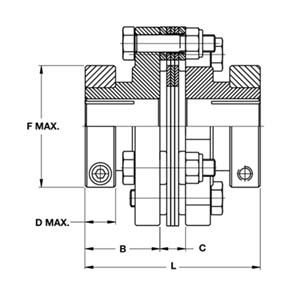

This design reflects top-notch engineering to achieve this highly efficient, cycling through use of an integrated servomotor/coupling combination. The off-the-shelf modules include a Zero-Max Model 6A37C single flex CD coupling with clamp style hubs which connects directly to a 2 Kw Yaskawa 3000 rpm vertically mounted servomotor (4 Kw for the horizontal stations). The motor/coupling combination provides rapid start/stop film advance while preventing misalignment problems before they occur. The motor draws the film smoothly, in-register while the CD coupling dampens any backlash forces, thereby eliminating any chance of a misfeed of the system's polypropylene film. With two such stations in a typical pouching system, this is a tall order indeed.

|

|

|

Note location of CD coupling attached directly to the servo motor shaft. Assembly is done with a single set screw at each end of the coupling. No special alignment or lasers are needed for installation. |

|

"We have a zero backlash requirement for the indexing operation in our pouching systems," reports Scott Risnes, senior engineer for Robert's Packaging. "Any backlash or improper hesitation in the drawing cycle can cause misalignment of the film for the heat sealing operation. The Zero-Max CD coupling connected directly to the Yaskawa servo motor handles this requirement easily and prevents any backlash from occurring."

This is significant since pouch travel for each .3333 second sealing and cutoff cycle ranges from 4 inches for the smaller pouches to 12 inches for the largest pouches, depending on machine model (pouch width is either 4 to 12 inches).

CD Coupling Has Unique Zero Backlash Design –

-- Pouches Hit Alignment "Spot" Every Indexing Cycle

Ideal for the Robert's Packaging pouching application, the CD coupling has many of the best features of other coupling designs with an important exception – its patented composite disc pack design. While the CD coupling transmits torque similar to any conventional coupling, it does a better job of dampening backlash and shock without the coupling fatiguing which can occur in a fast-moving system like Robert's Packaging. It accomplishes this through a patented unique open arm disc design made of highly durable composite disc material. This design absorbs and cushions any tendency for backlash from the servomotor's intermittent motion.

|

|

| CD® coupling disc pack. The coupling transmits torque between shaft coupling hubs similar to any conventional coupling. Yet the disc provides greater flexibility, misalignment, longer life, and damps shock and vibration through its unique patented open arm design with the use of highly durable composite material. | |

The system's pouch forming accuracy is monitored each indexing cycle by an Allen Bradley optical reader, which, Risnes says, "hits a tiny target spot on the pouch face without fail every time."

Another benefit Robert's Packaging found using the CD coupling was that it allowed for the use of a single flex, single disc model, which is less costly and does the work of most other metal double disc designs. It does so using less space with greater misalignment capability.

While misalignment isn't the major consideration in the Robert's Packaging pouching system, it does make a difference in assembly time. No lasers or special alignment tools are needed. The clamp style hub model used allows for fast installation by tightening just one screw on each hub of the coupling. For the Robert's Packaging application, the servo motor's 35 mm shaft diameter dictated the choice of the Model 37 size coupling, according to Risnes, which proved more than adequate for the system.

CD Coupling Outlasts Gearbox

As for performance, Risnes reports, "Once installed, you can forget the couplings because they never need service. All of ours over the years have performed without a problem. We have several systems in the field that are six years old and the CD's continue to operate 24/7 and are only stopped for 2 minutes to load new film every 2 hours or so. I know of one application using one of the very first Zero-Max CD couplings pouching walnuts where the couplings continue to operate like new. They're really durable couplings. In fact, I knew of one connected to a gearbox where the gearbox failed but the coupling continued performing satisfactorily. We never considered any other coupling design for our servo motors but the CD coupling."

For more information on Robert's Packaging stand-up automated pouching systems, call 269-962-5525. Website: www.robertspackaging.com. Or write to Robert's Packaging, 126 Avenue C, Battle Creek, Michigan 49015.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.