Applications for Zero-Max Motion Control Devices

Spee-Dee Packaging Uses Zero-Max CD Couplings To Handle High Speed, High Torque Motion In Its Auger Filling System For Food Products

Promotes Smooth, Accurate Operation Of Quarter-Second Fill Cycles

Sturtevant, WI: Auger systems using direct drive servo motors for blending and filling food pouches and packages are an improvement over stepper motor and traditional clutch/brake systems resulting in increased speed, repeatable filling accuracy and reduced system maintenance.

|

|

|

Spee-Dee Packaging Machinery, Inc. canted head dual auger system fills two dry food products with different characteristics through a single tube and into one pouch or package |

Spee-Dee auger with conveyor |

Operating at up to 120 fills per minute, these new servo driven systems when equipped with Zero-Max CD couplings are able to fill dry products with repeatable accuracy into one pouch or package. The rapid start/stop augering motion is smoothed out by the coupling so there is no undesirable resonance or vibration during operation. These high speed filling cycles are programmed to fill accurately to specified weights within a gram eliminating expensive product "giveaway."

|

|

|

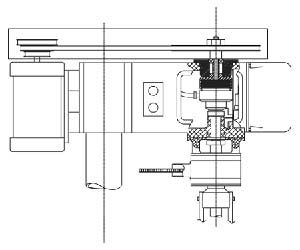

Traditional systems connected motor to clutch/brake setup via pulleys and driving belt. Design is shown operating with high maintenance needs compared to the Spee-Dee design. |

Spee-Dee augering system design has servo motor connecting directly to CD Coupling and high speed filling mechanism. Start/stop augering motion is smoothed out by the coupling which produces up to 120 fills per minute. |

Spee-Dee® Packaging Machinery, Inc. is the innovator of these servo driven augering systems. Designed for integration into a complete filling line, "the engineering behind these auger systems is simple yet elegant", according to Timm Johnson, Spee-Dee vice president sales/marketing. "These systems have the auger mounted vertically in the form/seal system which takes much less floor space than horizontal systems. The vertical design with 10 and 16 gallon feeding hoppers on top also facilitate the high speed fill cycles within the line.

Coupling Has Zero Backlash Design – Features That Adapt

Well To Augers 5 Inches To 5 Feet In Length

"We tried other couplings when using stepper motors in our systems years ago," reports Johnson. "None were rigid enough and when tested, they developed resonance problems. So we went to the CD couplings from Zero-Max on all of our servo motors. They gave us the torque rigidity we needed."

|

|

|

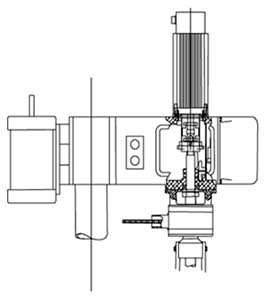

Note location of CD coupling attached directly to the servo motor shaft. Assembly is done with a single set screw at each end of the coupling. No special alignment of lasers are needed for installation. |

|

Smooth operation of the augering system is critical to achieve the highest fill rates with repeatable accuracy. These are governed by ingredient consistency and flow, diameter and length of the auger and the speed at which the auger turns, controlling the torque or pressure and governing food ingredient flow into a pouch or package.

"In designing these auger systems, we carefully calculate desired fill rates for specific ingredients and package sizes which dictate auger diameter and length and other important variables such as motor requirements. All of these systems are designed to operate at top speed without problems so they can perform 24/7 with as little downtime and maintenance as possible. One of the keys is the coupling which dampens any tendency of vibration or resonance which can throw off or interrupt the filling cycles," says Johnson.

Ideal for this type of servo motor application, the CD coupling has many of the best features of other coupling designs with one notable exception – its patented composite disc pack. While the CD coupling transmits torque similar to any conventional coupling, the composite disc pack does a better job of dampening backlash and shock without the coupling fatiguing, which can occur in a fast-moving system with high cycle rates.

|

|

CD® coupling disc pack. The coupling transmits torque between shaft coupling hubs similar to any conventional coupling. Yet the disc provides greater flexibility, misalignment, longer life, and damps shock and vibration through its unique patented open arm design with the use of highly durable composite material. |

The reason is that the CD coupling has a unique open arm disc design (patented) made of highly durable composite disc material. This design absorbs and cushions any tendency for vibration or resonance from the servo motor's intermittent motion. The motors are Bosch Rexroth servos, 2 Kw, 0 to 1400 rpm. The CD coupling used for most of the company's auger systems is the 6A26-AC model, which has a 2.60 diameter and has aluminum clamp style hubs. Connecting directly to the servo motor shaft at one end, the CD coupling connects on the other end to a self-aligning ball bearing attached to a middle support plate. The bearing assembly connects to the auger. One of these augers is employed per filling line. There are single, twin, quad and as many as 10 dual auger setups designed by Spee-Dee Packaging.

Operating torque for each auger varies depending on the consistency of the ingredients, their volume and the size of the auger tooling which ranges from 5 inches in length to 5 feet. According to Johnson, these systems accelerate from 0 to a maximum 1,400 rpm with the coupling capable of handling top torque loads of 3785 in. lbs.

Another benefit Spee-Dee Packaging experienced with the CD coupling was that it allowed for use of a single flex, single disc model. These are less costly and do the work of most other double disc designs. Also the space used is less and the misalignment capability is greater. Aligning the coupling in the setup is easy, requiring no special alignment tools, according to Johnson. The clamp style hub model allows for fast installation by tightening just one screw on each hub of the coupling.

"We've had no problems with backlash or vibration using the CD couplings," reports Johnson. We've been using them for over 4 years with several hundred in the field."

For more information on Spee-Dee Packaging auger filling systems, call toll free

877-375-2121, website www.spee-dee.com. Or write to Spee-Dee Packaging Machinery, Inc. 9950 Durand Ave., Sturtevant, WI 53177.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.