Applications for Zero-Max Motion Control Devices

Pages:

1

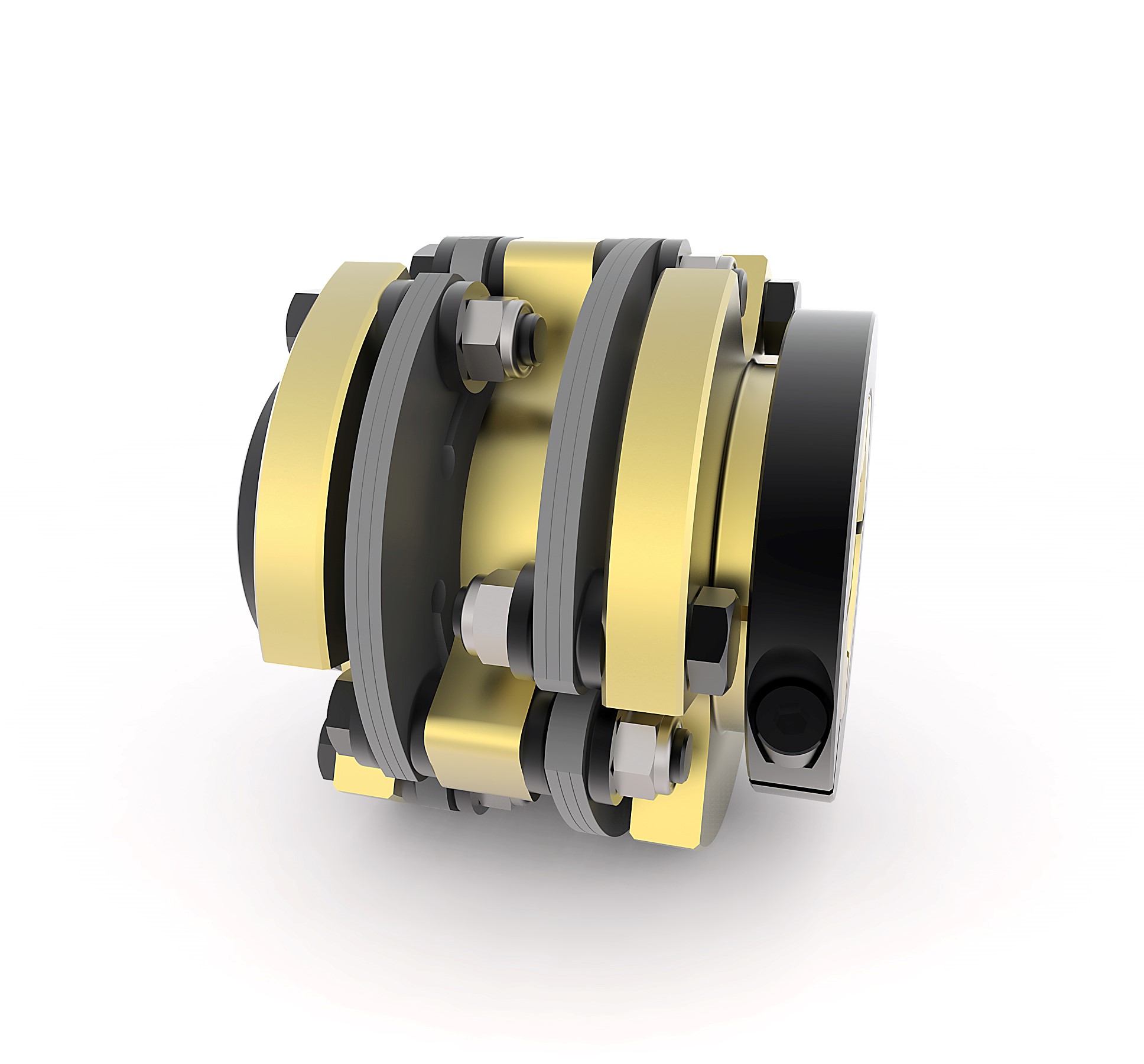

Custom CD® Coupling Success Story: Extra Parallel Misalignment Capacity in Restricted Operating Space

Connected motion components in a composite fiber processing system needed extra parallel misalignment capacity to prevent premature bearing failure and oil leakage. Zero-Max solved this problem by creating a custom, shortened Double Flex CD® Coupling.

Connected motion components in a composite fiber processing system needed extra parallel misalignment capacity to prevent premature bearing failure and oil leakage. Zero-Max solved this problem by creating a custom, shortened Double Flex CD® Coupling.

Preventing Excess Stress and Wear with Customized Double Flex CD® Couplings

The original machine design called for a single flex, steel disc coupling to connect the system motor to a gearbox. When operating, the steel disc coupling did not allow enough parallel misalignment to protect connected components from excess stress and wear. This issue caused component failure leading to system downtime, with time and money lost restarting the equipment.Zero-Max proposed engineering a shortened version of its Model 6P60C Double-Flex CD® coupling to deliver the misalignment capacity needed in the small available space. These custom CD couplings featured composite disc-packs that handled extra misalignment and minimized reaction loads in the confined operating space better than steel disc couplings. Our special design solution delivered:

- A peak torque value of 12,700 in-lbs.

- Torsionally stiff design capable of operating at speeds up to 4,400 rpm, far above the system’s upper performance requirements.

- Very low reaction loads on the system’s shaft bearings.

- Up to 3 degrees angular misalignment while also allowing 0.069 (1.8mm) parallel and 0.260 (6.6mm) axial misalignment.

- Aluminum hubs to minimize inertia.

Solving Mechanical Misalignment Challenges with Our Engineering Expertise

Zero-Max’s success stems from applying several engineering disciplines to each shaft coupling challenge. These disciplines include metallurgy and alloy material design, composite disc formation, disc deflection control, precision fastening of components and dynamic coupling balancing.Each engineering discipline requires precise control of the coupling body, stiffness properties of the composite disc, and the overall weight of the coupling assembly.

Custom CD couplings designs from Zero-Max help solve common and unique motion control challenges, including handling high power in a small space, blind fit couplings, large scale floating shaft couplings, high misalignment and high torque couplings, high-speed couplings, and so much more. Read about other applications for our custom CD couplings.

Zero-Max is a premier supplier of high-performance motion control and power-transmission components. Our engineers work with you to provide unique solutions for any application. Call or send us a message to discuss how our CD couplings can help you solve complex misalignment challenges.

Locate your nearest sales representative, request a quote, or contact us for all your application requirements.